Plasma Cutting

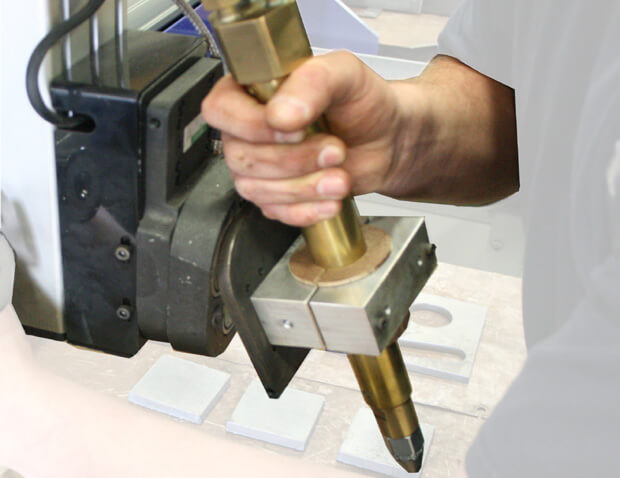

TURBO FLAME™ TORCH WITH SURESTOP COLLISIONS SENSOR

The Turbo Flame™ Torch is accurately positioned through the shared use of the smooth, ball-screw driven OL Lifter, featuring a SureStop Collision Sensor. Cutting up to 20% faster than other torches, regardless of fuel gas used.

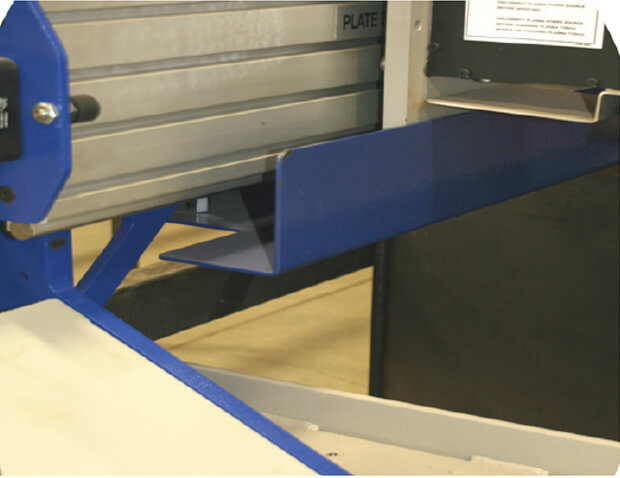

PLATE RIDER ATTACHMENT

The Plate Rider Attachment provides downward pressure to keep material flat during plate cutting applications. Easily removed for thick plate cutting.

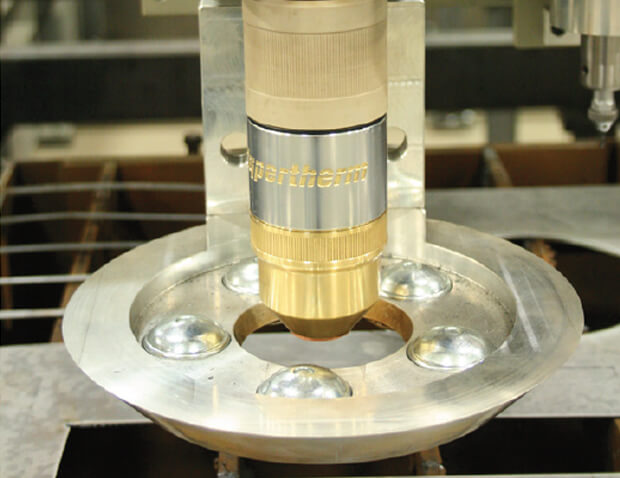

OL100s PLASMA LIFTER WITH SURESTOP COLLISION SENSOR

OL Plasma Lifter with true arc-voltage height control maintains consistent height on all surfaces. The SureStop Collision Sensor protects the torch while cutting and jogging to prevent damage to the torch and lifter.

400 AMP HEAVY-CUTTING PACKAGE

The HPR400XD or Spirit® II 400 Amp plasma systems pierces up to two-inch thick mild steel. 400 Amps, productivity increases with faster speeds on thinner materials. Includes special heavy-duty slat frames, slats and shielding.